Ever wondered why some engines feel like they're begging to rev, while others just grunt with low-end power? There's a hidden ratio lurking within your engine's design that dictates its personality: the bore-stroke ratio. It’s a key element often overlooked, but understanding it can unlock a whole new level of appreciation for how engines work and why they behave the way they do.

Many car enthusiasts struggle to understand the technical jargon surrounding engine specifications. They might be bombarded with terms like "bore," "stroke," and "ratio" without a clear understanding of how these elements translate to real-world driving experiences. This lack of understanding can lead to confusion when trying to choose the right engine for their needs or when trying to optimize their existing engine's performance.

This article aims to demystify the bore-stroke ratio, explaining it in simple, understandable terms and illustrating how it affects an engine's performance characteristics. We'll break down the concepts, discuss the trade-offs, and show you how to apply this knowledge to better understand and appreciate the engines that power our vehicles.

In essence, the bore-stroke ratio is a simple comparison of the cylinder's diameter (bore) to the distance the piston travels (stroke). This ratio heavily influences the engine's torque, horsepower, and overall driving feel. A larger bore generally leads to higher RPM power, while a longer stroke tends to favor low-end torque. By understanding this relationship, you can better analyze engine specs and predict its performance. Related keywords: engine performance, bore, stroke, torque, horsepower, engine design.

The "Square" Engine: Finding the Balance

The target of understanding the "square" engine is to appreciate how engines with roughly equal bore and stroke dimensions strike a balance between low-end torque and high-RPM power. These engines often provide a versatile driving experience suitable for various applications. They are neither specialized for brute force at low speeds nor solely focused on peak horsepower at high engine speeds. They offer a more rounded, general-purpose performance profile, making them suitable for daily driving or applications where consistent power across the RPM range is desired.

I remember the first time I really understood the concept of a "square" engine. I was helping a friend rebuild a classic inline-six engine for his vintage truck. The engine was known for its reliability and decent performance across the board. As we were measuring the bore and stroke, I noticed they were almost identical. My friend explained that this "square" design was a key reason why the engine was so versatile. It wasn't a high-revving screamer like some sports car engines, but it had plenty of torque for hauling and could still hold its own on the highway. That's when it clicked for me – the bore-stroke ratio wasn't just some abstract number; it directly translated to how the engine felt and performed.

A square engine is defined as one where the bore diameter and stroke length are nearly equal. This balance results in an engine that offers a good compromise between low-end torque and high-RPM horsepower. Square engines tend to have a broader powerband, making them suitable for a wide range of applications, from everyday passenger cars to light-duty trucks. They don't excel in any one particular area but instead provide a well-rounded and usable power delivery. Think of engines that are used in everyday sedans; many fall into this category. The designers aim for a usable power band for daily driving, not necessarily peak performance at either extreme.

This design choice is often favored when engine longevity and reliability are prioritized alongside performance. The relatively short stroke reduces piston speeds and stresses, contributing to a longer engine lifespan. The more balanced forces within the engine also minimize vibrations and wear. While not as specialized as oversquare (larger bore than stroke) or undersquare (smaller bore than stroke) engines, the "square" design offers a compelling blend of practicality and performance, making it a popular choice for many applications. In essence, a square engine is a jack-of-all-trades, master of none, but perfectly capable of handling a variety of driving situations with competence and reliability.

What is the Bore-Stroke Ratio?

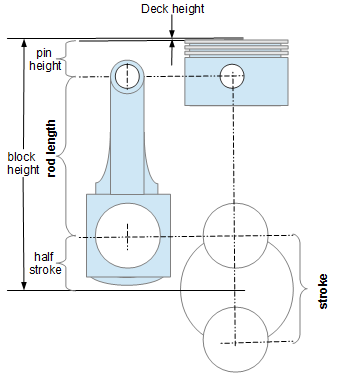

The bore-stroke ratio is a fundamental characteristic of an internal combustion engine. It's a simple numerical comparison that expresses the relationship between the diameter of the engine's cylinders (the bore) and the distance the piston travels within that cylinder (the stroke). Specifically, it's calculated by dividing the bore diameter by the stroke length. The resulting number gives you a sense of the engine's basic design and how it's likely to perform.

Understanding this ratio is crucial because it dramatically influences an engine's performance characteristics. A high bore-stroke ratio (oversquare engine, where the bore is larger than the stroke) generally favors higher engine speeds (RPMs) and can lead to greater peak horsepower. This is because the larger bore allows for bigger valves, improving airflow at high speeds. Conversely, a low bore-stroke ratio (undersquare engine, where the stroke is longer than the bore) typically results in higher torque at lower engine speeds. The longer stroke provides more leverage on the crankshaft, increasing the turning force. The third case, a "square" engine, is where the bore and stroke are nearly equal, striking a balance between torque and horsepower.

Consider this: imagine pushing a heavy box. A long lever arm (analogous to a long stroke) makes it easier to get the box moving, representing the high torque of an undersquare engine. Now, imagine spinning a lightweight wheel. A larger diameter wheel (analogous to a larger bore) can spin faster and generate more power at higher speeds, representing the high-RPM potential of an oversquare engine. The bore-stroke ratio is a fundamental design parameter that engineers carefully consider when developing an engine to meet specific performance goals. The choice of bore and stroke is not arbitrary; it's a carefully calculated decision that impacts the engine's entire character and suitability for different applications.

The History and Myth of Bore-Stroke Ratio

The history of the bore-stroke ratio is intertwined with the evolution of the internal combustion engine itself. Early engines, often designed for industrial applications, tended to have long strokes and relatively small bores. This undersquare design prioritized torque for driving machinery and heavy loads at low speeds. As engine technology advanced and applications expanded to transportation, engineers began experimenting with different bore-stroke configurations to optimize performance for various needs.

One enduring myth surrounding the bore-stroke ratio is that "bigger is always better" when it comes to the bore. While a larger bore can certainly contribute to higher peak horsepower, it's not the sole determinant of engine performance. A large bore alone doesn't guarantee a superior engine; it needs to be coupled with proper valve design, camshaft timing, and other engine components to fully realize its potential. In fact, an excessively large bore can lead to combustion inefficiencies and other issues if not carefully engineered.

Throughout the 20th century, the evolution of racing engines pushed the boundaries of bore-stroke ratios. The desire for higher and higher RPMs led to the development of increasingly oversquare engines, with short strokes and large bores. These engines were capable of generating tremendous horsepower but often sacrificed low-end torque. This trend, however, isn't always applicable to everyday engines. Modern engine design often involves a complex interplay of factors, including bore-stroke ratio, combustion chamber design, fuel injection systems, and turbocharging, to achieve the desired performance characteristics for specific applications, whether it's fuel efficiency, high-performance, or a balance of both. The "best" bore-stroke ratio depends entirely on the intended use of the engine and the overall design strategy.

The Hidden Secret of Bore-Stroke Ratio

The hidden secret of the bore-stroke ratio lies not just in its direct influence on torque and horsepower, but also in its indirect effects on other crucial engine parameters. It's a foundational element that impacts everything from piston speed and combustion efficiency to engine packaging and thermal management. Understanding these subtle relationships is key to truly grasping the significance of this seemingly simple ratio.

For example, a shorter stroke, characteristic of an oversquare engine, typically results in lower piston speeds at a given RPM. This can reduce wear and tear on the engine's internal components, allowing it to rev higher and potentially last longer. However, a shorter stroke can also reduce the time available for combustion, potentially impacting efficiency and emissions. Conversely, a longer stroke, common in undersquare engines, increases piston speed, which can lead to higher frictional losses and increased stress on the connecting rods and bearings. However, the longer dwell time at top dead center can improve combustion efficiency in some cases.

The bore-stroke ratio also has implications for engine packaging. A very long stroke can result in a taller engine block, which may not fit easily into certain vehicle designs. A large bore, on the other hand, can increase the overall width of the engine. These physical constraints often play a role in the final decision-making process during engine development. Furthermore, the bore size has a direct relationship with valve size. A larger bore generally allows for larger valves, improving airflow into and out of the cylinder. This enhanced airflow is essential for achieving high-RPM power. The "hidden secret" is that the bore-stroke ratio is a fundamental constraint that influences a cascade of design decisions, ultimately shaping the engine's overall character and capabilities. It's a delicate balancing act, where optimizing one aspect often requires compromises in others. A deep understanding of these interdependencies is what separates a good engine design from a truly exceptional one.

Recommendations for Bore-Stroke Ratio

Recommendations for bore-stroke ratio depend heavily on the intended application of the engine. There's no one-size-fits-all answer; the "best" ratio is the one that best aligns with the desired performance characteristics and driving experience. Consider these general guidelines based on different applications:

For everyday passenger cars and light-duty trucks, a "square" or slightly undersquare engine is often recommended. This provides a good balance of low-end torque for everyday driving and sufficient horsepower for highway cruising. Fuel efficiency and engine longevity are also important considerations in this category, and these designs tend to offer a good compromise in these areas. The emphasis is on usability and reliability, rather than outright performance.

For high-performance sports cars and racing applications, an oversquare engine is generally preferred. The larger bore allows for larger valves and improved airflow, which is crucial for achieving high RPMs and peak horsepower. Torque is often sacrificed in favor of top-end power. These engines are designed to excel on the track or in spirited driving situations where high engine speeds are the norm. For applications where torque is paramount, such as heavy-duty trucks and towing vehicles, an undersquare engine is typically the best choice. The long stroke provides ample leverage for generating high torque at low engine speeds, making it easier to move heavy loads. Fuel efficiency may be less of a concern in these applications compared to sheer pulling power. Ultimately, the choice of bore-stroke ratio is a complex decision that requires careful consideration of the specific requirements of the application. It's essential to weigh the trade-offs between torque, horsepower, fuel efficiency, and engine longevity to arrive at the optimal design. Consulting with experienced engine builders and tuners can also provide valuable insights and guidance in this process.

Bore-Stroke Ratio and Fuel Efficiency

The bore-stroke ratio indirectly influences fuel efficiency through several mechanisms. While not the sole determinant, it plays a significant role in shaping the engine's combustion characteristics, friction losses, and thermal efficiency, all of which contribute to overall fuel consumption. Generally, engines with longer strokes (undersquare) tend to have slightly better thermal efficiency, meaning they convert more of the fuel's energy into useful work rather than heat.

This is because the longer dwell time at top dead center allows for more complete combustion, especially at lower engine speeds. However, the longer stroke also increases piston speed, leading to higher friction losses and potentially offsetting some of the efficiency gains. Oversquare engines, with their shorter strokes, typically have lower piston speeds, which can reduce friction losses. However, the shorter dwell time at top dead center may result in less complete combustion, especially at lower engine speeds. This can lead to increased emissions and reduced fuel efficiency.

Furthermore, the bore-stroke ratio influences the surface area to volume ratio of the combustion chamber. A smaller bore, characteristic of an undersquare engine, tends to have a lower surface area to volume ratio, which can reduce heat losses to the cylinder walls and improve thermal efficiency. Modern engine designs often incorporate advanced technologies such as direct fuel injection, variable valve timing, and turbocharging to mitigate the potential downsides of both oversquare and undersquare designs. These technologies allow engineers to optimize combustion and reduce friction losses, regardless of the bore-stroke ratio. Ultimately, the impact of the bore-stroke ratio on fuel efficiency is complex and intertwined with other engine design parameters. While it's a factor to consider, it's not the only or even the most important determinant of fuel consumption. Modern engines are sophisticated systems that are carefully optimized to achieve the best possible balance of performance, fuel efficiency, and emissions.

Tips for Understanding Bore-Stroke Ratio

Understanding the bore-stroke ratio and its impact on engine performance can be challenging, but here are some helpful tips to demystify the concept and make it more accessible:

First, visualize the relationship. Imagine the bore as the diameter of a circle and the stroke as the length of a line segment within that circle. A large circle with a short line represents an oversquare engine, while a small circle with a long line represents an undersquare engine. This visual analogy can help you grasp the fundamental geometry of the bore-stroke ratio. Next, focus on the extremes. Think of a high-revving motorcycle engine as an example of an oversquare design, optimized for peak horsepower. Then, consider a large diesel truck engine as an example of an undersquare design, built for maximum torque at low speeds. These extreme examples can help you internalize the performance characteristics associated with each type of bore-stroke ratio.

Third, don't get bogged down in the numbers. While the bore-stroke ratio is a numerical value, it's more important to understand the underlying principles than to memorize specific ratios. Focus on the general trends and how they relate to engine performance. Finally, research specific engine examples. Look up the bore-stroke ratios of different engines and compare their performance characteristics. This hands-on approach can help you solidify your understanding and see how the bore-stroke ratio plays out in the real world. By combining these tips, you can develop a more intuitive understanding of the bore-stroke ratio and its impact on engine performance.

Understanding Over-square and Under-square Engines

Oversquare engines, characterized by a larger bore than stroke, typically excel in high-RPM performance. This design allows for larger valves, which, in turn, improves airflow into and out of the cylinders at high engine speeds. The shorter stroke also reduces piston speed, minimizing wear and tear and allowing the engine to safely rev higher. However, oversquare engines often sacrifice low-end torque, which can make them feel less responsive at lower engine speeds.

Under-square engines, with a longer stroke than bore, are known for their strong low-end torque. The longer stroke provides more leverage on the crankshaft, generating greater turning force at lower engine speeds. This makes under-square engines ideal for applications where pulling power is essential, such as trucks and towing vehicles. However, the longer stroke also increases piston speed, which can lead to higher friction losses and limit the engine's maximum RPM. The choice between oversquare and undersquare engines ultimately depends on the specific performance goals and intended application.

Modern engine designs often incorporate advanced technologies to mitigate the limitations of both oversquare and undersquare designs. For example, variable valve timing can help to improve airflow at both low and high engine speeds, while turbocharging can boost torque across the RPM range. These technologies allow engineers to fine-tune the engine's performance characteristics, regardless of the bore-stroke ratio. Understanding the trade-offs between oversquare and undersquare engines is essential for making informed decisions about engine selection and modification. By considering the specific needs of the application and the available technologies, it's possible to choose or build an engine that delivers the desired performance characteristics.

Fun Facts of Bore-Stroke Ratio

Here are some fun facts about the bore-stroke ratio that might surprise you:

Did you know that the legendary Ferrari V12 engines of the 1960s and 70s were renowned for their oversquare designs, which contributed to their incredible high-RPM performance and distinctive sound? These engines were true engineering masterpieces, showcasing the potential of the oversquare design in the world of high-performance sports cars. On the other hand, early steam engines, which predated the internal combustion engine, often featured extremely long strokes relative to their bore. This design was optimized for generating maximum torque at very low speeds, which was essential for powering industrial machinery.

The bore-stroke ratio can even influence the sound of an engine. Oversquare engines tend to have a higher-pitched, more raspy exhaust note, while undersquare engines often produce a deeper, more guttural sound. This is due to the different combustion characteristics and exhaust gas velocities associated with each type of design. Some engine manufacturers have even experimented with unconventional bore-stroke ratios to achieve specific performance goals. For example, some engines have been designed with extremely short strokes to minimize piston speed and allow for incredibly high RPMs. Others have been designed with very long strokes to maximize torque at extremely low speeds. These unconventional designs often push the boundaries of engine technology and challenge conventional wisdom. Exploring these fun facts can provide a deeper appreciation for the ingenuity and creativity that goes into engine design.

How to Calculate Bore-Stroke Ratio

Calculating the bore-stroke ratio is a straightforward process that involves just two measurements and a simple division. Here's a step-by-step guide:

First, you'll need to find the bore and stroke specifications for the engine you're interested in. This information is typically available in the engine's technical documentation or online resources. The bore is the diameter of the engine's cylinders, while the stroke is the distance the piston travels within the cylinder. Both measurements are usually expressed in millimeters (mm) or inches (in). Once you have the bore and stroke measurements, simply divide the bore by the stroke. The formula is: Bore-Stroke Ratio = Bore / Stroke.

For example, if an engine has a bore of 86 mm and a stroke of 77 mm, the bore-stroke ratio would be 86 mm / 77 mm = 1.12. This indicates an oversquare engine, as the bore is larger than the stroke. To interpret the result, remember that a ratio greater than 1 indicates an oversquare engine, a ratio less than 1 indicates an undersquare engine, and a ratio close to 1 indicates a "square" engine. With this simple calculation, you can quickly determine the bore-stroke ratio of any engine and gain insights into its potential performance characteristics.

What if Bore-Stroke Ratio Changed?

Changing the bore-stroke ratio of an engine is a significant modification that can have a profound impact on its performance characteristics. It's not a simple task, and it typically requires extensive engine rebuilding and modifications. However, the potential benefits can be substantial, depending on the desired outcome.

If you increase the bore while keeping the stroke the same, you'll effectively create an oversquare engine. This can lead to higher RPMs and increased peak horsepower, but it may also reduce low-end torque. Conversely, if you increase the stroke while keeping the bore the same, you'll create an undersquare engine. This can boost low-end torque but may limit the engine's maximum RPM. Changing the bore-stroke ratio often involves replacing the pistons, connecting rods, and crankshaft, as these components are directly related to the bore and stroke measurements. It may also require modifications to the cylinder head to accommodate larger valves or improve airflow. These modifications can be complex and expensive, so it's essential to carefully consider the costs and benefits before undertaking such a project.

It's also important to note that changing the bore-stroke ratio can affect other engine parameters, such as compression ratio and combustion chamber volume. These changes may require further adjustments to the engine's fuel and ignition systems to ensure optimal performance. Modifying the bore-stroke ratio is not a task for the faint of heart. It requires a deep understanding of engine mechanics and a willingness to invest significant time and resources. However, for those who are seeking to optimize their engine's performance for a specific application, it can be a worthwhile endeavor. Consulting with experienced engine builders and tuners is highly recommended before embarking on such a project.

Listicle of Bore-Stroke Ratio

Here's a quick listicle summarizing the key aspects of the bore-stroke ratio:

1. Definition: The bore-stroke ratio is the ratio of the engine cylinder's bore (diameter) to the piston's stroke (distance traveled).

2. Oversquare Engines: These engines have a larger bore than stroke and tend to produce more horsepower at higher RPMs.

3. Undersquare Engines: These engines have a longer stroke than bore and tend to produce more torque at lower RPMs.

4. Square Engines: These engines have roughly equal bore and stroke dimensions, offering a balance of torque and horsepower.

5. Performance Impact: The bore-stroke ratio significantly influences engine torque, horsepower, and overall driving feel.

6. Fuel Efficiency: The bore-stroke ratio can indirectly affect fuel efficiency through its influence on combustion and friction.

7. Applications: The ideal bore-stroke ratio depends on the intended application, with oversquare engines favored for racing and undersquare engines preferred for towing.

8. Calculation: The bore-stroke ratio is calculated by dividing the bore by the stroke (Bore / Stroke).

9. Modification: Changing the bore-stroke ratio requires significant engine rebuilding and modifications.

10. Hidden Secrets: The bore-stroke ratio also indirectly influences piston speed, combustion efficiency, engine packaging, and thermal management.

Question and Answer about Bore-Stroke Ratio

Here are some frequently asked questions about the bore-stroke ratio:

Q: What is a good bore-stroke ratio for a daily driver?

A: For a daily driver, a "square" or slightly undersquare engine is often a good choice. This provides a balance of low-end torque for everyday driving and sufficient horsepower for highway cruising.

Q: Does a larger bore always mean more power?

A: Not necessarily. While a larger bore can contribute to higher peak horsepower, it's not the sole determinant of engine performance. Other factors, such as valve design, camshaft timing, and exhaust system design, also play a significant role.

Q: Can I change the bore-stroke ratio of my engine?

A: Yes, but it's a significant modification that requires extensive engine rebuilding and modifications. It's essential to carefully consider the costs and benefits before undertaking such a project.

Q: Is it possible to have too much bore or too much stroke?

A: Yes, both excessive bore and excessive stroke can have negative consequences. An excessively large bore can lead to combustion inefficiencies, while an excessively long stroke can increase piston speed and stress on engine components.

Conclusion of Bore-Stroke Ratio – Engine Performance Explained in Simple Terms

The bore-stroke ratio is a fundamental aspect of engine design that profoundly impacts performance. Understanding this ratio provides valuable insight into an engine's character, capabilities, and suitability for different applications. From the high-revving thrills of oversquare engines to the low-end grunt of undersquare designs, the bore-stroke ratio shapes the driving experience in subtle yet significant ways. Whether you're a seasoned gearhead or simply curious about how engines work, grasping this concept will undoubtedly deepen your appreciation for the intricate world of automotive engineering. By considering the principles outlined in this article, you can better analyze engine specifications, predict performance characteristics, and ultimately, make more informed decisions about the engines that power our vehicles.