Ever wondered about that little valve in your car's engine that's helping to keep the air cleaner and your fuel economy up? It's probably the Exhaust Gas Recirculation (EGR) valve, and it plays a more important role than you might think!

Many drivers face the challenge of understanding the complex systems within their vehicles, often leading to unexpected repair bills and a general feeling of being in the dark about how their cars actually work. Understanding the purpose and function of components like the EGR valve can empower drivers to make informed decisions about maintenance and care, potentially saving them money and preventing future headaches.

The goal of this article is to demystify the Exhaust Gas Recirculation (EGR) system, exploring its design, function, and benefits. We'll break down the technical jargon and explain how this system works to reduce harmful emissions and improve engine efficiency. By the end, you'll have a solid understanding of this crucial component and its impact on your vehicle's performance and the environment.

In essence, this post will delve into the world of Exhaust Gas Recirculation (EGR) systems, examining their design principles, operational mechanisms, and the advantages they offer in terms of reduced emissions and enhanced engine performance. We will cover topics such as EGR valve function, EGR system design, NOx reduction, engine efficiency, and the environmental benefits of this technology.

Understanding the EGR Valve: A Personal Anecdote

The first time I really understood what an EGR valve was, it was because I was staring at a check engine light that wouldn't go away. My old pickup truck, a trusty beast that had seen better days, started running rough, and the dreaded light illuminated my dashboard. After a bit of research (and a lot of cursing), I stumbled upon the EGR valve as a potential culprit.

Armed with a Haynes manual and a shaky internet connection, I decided to tackle the job myself. Let me tell you, it wasn't pretty! The valve was caked in carbon deposits, a testament to years of faithful service. After a meticulous cleaning (and a few scraped knuckles), I reinstalled the valve and crossed my fingers. To my surprise, the engine purred like a kitten, and the check engine light vanished! That experience sparked my curiosity about the EGR system and its impact on engine performance and emissions.

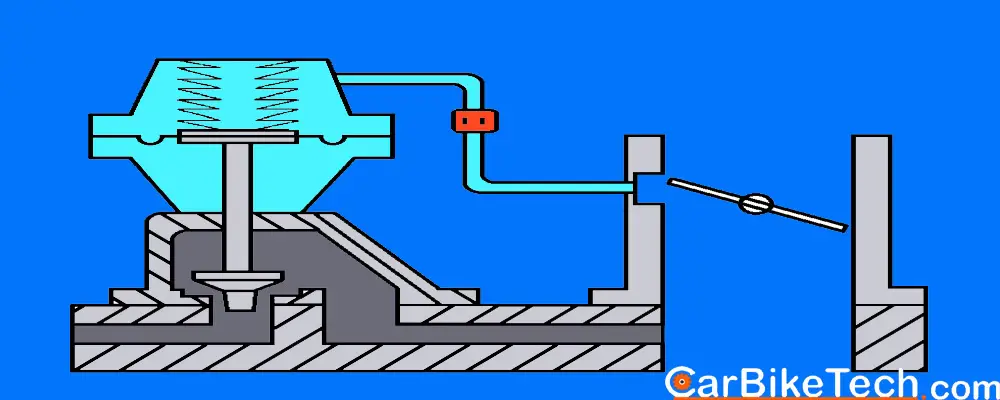

The EGR valve is a critical component within the EGR system, acting as a gateway for exhaust gases to re-enter the intake manifold. Its primary function is to control the amount of exhaust gas recirculated into the engine. The design of the EGR valve varies depending on the vehicle and engine type, but it generally consists of a valve body, a diaphragm, and a solenoid. The solenoid is controlled by the engine control unit (ECU), which determines when and how much exhaust gas to recirculate. This precise control is essential for optimizing engine performance and minimizing emissions, especially nitrogen oxides (NOx), which are harmful pollutants. Proper maintenance and understanding of the EGR valve are vital to ensure the efficient operation of the entire EGR system and the overall health of the vehicle.

How EGR Works: A Simplified Explanation

Imagine your engine as a powerful combustion chamber. It mixes air and fuel, ignites the mixture, and produces power. This process also generates exhaust gases, which contain harmful pollutants like nitrogen oxides (NOx). NOx forms when combustion temperatures are very high. This is where the EGR system steps in.

The EGR system cleverly recirculates a portion of these exhaust gases back into the intake manifold. This may sound counterintuitive – why put exhaust back into the engine? The key is that exhaust gases are inert and don't burn. When mixed with the fresh air-fuel mixture, they lower the overall combustion temperature. Lower combustion temperatures mean less NOx is produced. It's like adding water to a boiling pot – it cools things down!

The EGR system typically includes an EGR valve, EGR cooler (in some applications), and various sensors and actuators controlled by the engine control unit (ECU). The ECU monitors engine conditions, such as temperature, load, and speed, and adjusts the EGR valve opening to regulate the amount of exhaust gas recirculated. This precise control ensures optimal NOx reduction without compromising engine performance. Modern EGR systems are highly sophisticated, employing feedback loops and adaptive strategies to maintain consistent and efficient operation across a wide range of driving conditions.

EGR History and Myths: Debunking Misconceptions

The concept of exhaust gas recirculation dates back to the early 20th century, but it wasn't until the 1970s that it became widely implemented in vehicles due to increasingly stringent emissions regulations. The initial EGR systems were relatively simple, often consisting of a vacuum-operated valve. Over time, EGR technology has evolved significantly, with modern systems incorporating electronic controls, sophisticated sensors, and even EGR coolers to enhance their effectiveness.

One common myth surrounding EGR systems is that they negatively impact engine performance. While it's true that excessive EGR can lead to reduced power and fuel economy, modern systems are designed to optimize EGR rates for specific engine conditions. In many cases, a properly functioning EGR system can actually improve fuel efficiency by reducing pumping losses and optimizing combustion. Another misconception is that EGR systems are prone to causing engine problems. While EGR valves can become clogged with carbon deposits over time, regular maintenance and proper driving habits can help prevent these issues. Furthermore, advanced diagnostic tools can quickly identify EGR-related problems, allowing for timely repairs and preventing further damage.

In reality, EGR systems are a crucial component of modern emissions control technology, playing a vital role in reducing air pollution and protecting the environment. Their evolution has been driven by the need to meet ever-tightening emissions standards while maintaining optimal engine performance and fuel economy.

The Hidden Secret of EGR: Fuel Efficiency

While the primary goal of EGR is to reduce NOx emissions, a lesser-known benefit is its potential to improve fuel efficiency. This might seem counterintuitive, as recirculating exhaust gas effectively displaces some of the fresh air-fuel mixture entering the engine. However, the key lies in the reduced pumping losses and improved combustion efficiency that EGR can provide.

When the throttle is partially closed, the engine has to work harder to draw air into the cylinders, creating a vacuum in the intake manifold. This is known as pumping loss. By recirculating exhaust gas, the EGR system effectively reduces the amount of fresh air the engine needs to pump, thereby reducing pumping losses and improving fuel economy. Furthermore, EGR can also improve combustion efficiency by diluting the air-fuel mixture, which leads to a slower and more complete burn. This can result in lower levels of unburned hydrocarbons and carbon monoxide in the exhaust, as well as improved fuel economy.

The exact impact of EGR on fuel efficiency depends on various factors, including engine design, driving conditions, and EGR system calibration. However, studies have shown that properly optimized EGR systems can provide a measurable improvement in fuel economy, particularly under part-load conditions. This hidden benefit of EGR highlights its importance not only for emissions control but also for overall engine efficiency and fuel conservation.

EGR Recommendations: Maintenance and Best Practices

To ensure the long-term health and efficiency of your EGR system, regular maintenance and adherence to best practices are essential. One of the most common issues with EGR systems is the buildup of carbon deposits in the EGR valve and intake manifold. These deposits can restrict airflow, impair valve operation, and ultimately lead to reduced engine performance and increased emissions.

To prevent carbon buildup, consider using high-quality fuels and performing regular engine maintenance, including oil changes and air filter replacements. Additionally, avoid prolonged idling, as this can contribute to carbon buildup. Periodically inspecting and cleaning the EGR valve can also help prevent problems. This can be done using specialized EGR valve cleaners or by manually removing and cleaning the valve. However, be sure to consult your vehicle's repair manual or a qualified mechanic before attempting any EGR valve cleaning.

If you notice any symptoms of EGR system problems, such as a rough idle, reduced power, or a check engine light, it's important to have your vehicle diagnosed by a qualified mechanic. Early detection and repair can prevent more serious damage and ensure that your EGR system continues to function properly. Finally, be aware that some aftermarket products, such as EGR delete kits, can have negative consequences for engine performance, emissions, and even legality. It's generally best to stick with original equipment manufacturer (OEM) parts and maintain your EGR system according to the manufacturer's recommendations.

EGR System Design: A Deeper Dive

The design of an EGR system is highly dependent on the engine type, size, and emissions requirements. However, most EGR systems share several key components, including the EGR valve, EGR cooler (in some applications), and various sensors and actuators. The EGR valve is the heart of the system, controlling the amount of exhaust gas recirculated into the intake manifold. It can be operated by vacuum, pressure, or electronic signals, depending on the design.

EGR coolers are used in some applications to further reduce the temperature of the recirculated exhaust gas. This is particularly important in diesel engines, where lower combustion temperatures can significantly reduce NOx emissions. EGR coolers typically consist of a heat exchanger that transfers heat from the exhaust gas to the engine coolant.

Sensors and actuators play a critical role in controlling the EGR system. The engine control unit (ECU) monitors various engine parameters, such as temperature, load, speed, and exhaust gas composition, and adjusts the EGR valve opening to optimize NOx reduction and engine performance. Actuators, such as solenoids and stepper motors, are used to precisely control the EGR valve opening based on the ECU's commands. Modern EGR systems often incorporate feedback loops and adaptive strategies to maintain consistent and efficient operation across a wide range of driving conditions.

EGR Tips and Tricks: Maximizing Efficiency

While maintaining your EGR system according to the manufacturer's recommendations is crucial, there are also some additional tips and tricks you can employ to maximize its efficiency and longevity. One simple tip is to avoid short trips, especially in cold weather. Short trips don't allow the engine to fully warm up, which can lead to increased carbon buildup in the EGR valve and intake manifold.

Another trick is to use a fuel additive specifically designed to clean fuel injectors and EGR valves. These additives can help remove carbon deposits and prevent future buildup, improving engine performance and fuel economy. However, be sure to choose a reputable brand and follow the manufacturer's instructions carefully.

Regularly inspecting your engine's vacuum hoses can also help ensure proper EGR system operation. Vacuum leaks can disrupt the EGR valve's ability to open and close properly, leading to reduced NOx reduction and engine performance. Finally, consider having your engine professionally tuned by a qualified mechanic. A proper engine tune can optimize the EGR system's calibration, ensuring that it's operating at its peak efficiency and minimizing emissions.

Troubleshooting Common EGR Problems

Despite regular maintenance, EGR systems can sometimes experience problems. One of the most common issues is a clogged EGR valve, which can result in a rough idle, reduced power, and a check engine light. Other common problems include vacuum leaks, faulty sensors, and damaged EGR coolers. Fortunately, many EGR problems can be diagnosed and repaired relatively easily.

If you suspect an EGR problem, start by checking the EGR valve for carbon deposits. If the valve is heavily clogged, it may need to be cleaned or replaced. Also, check the vacuum hoses for leaks or damage. A vacuum leak can disrupt the EGR valve's operation and lead to various engine problems. If you suspect a faulty sensor, use a scan tool to read the engine's diagnostic trouble codes (DTCs). These codes can help pinpoint the source of the problem and guide you towards the appropriate repair.

In some cases, EGR problems can be caused by underlying engine issues, such as a faulty oxygen sensor or a worn-out catalytic converter. Addressing these underlying issues can help prevent future EGR problems and ensure that your engine is operating at its peak efficiency. If you're unsure how to diagnose or repair an EGR problem, it's best to consult a qualified mechanic.

Fun Facts About EGR: A Little Trivia

Did you know that EGR systems were initially developed to reduce engine knocking rather than emissions? Early engineers discovered that recirculating exhaust gas could lower combustion temperatures and prevent premature detonation, which is the cause of engine knocking. While emissions reduction is now the primary goal of EGR, its ability to prevent engine knocking remains a valuable side benefit.

Another fun fact is that some modern engines use internal EGR, which doesn't require a separate EGR valve. Internal EGR is achieved by carefully controlling valve timing to trap a small amount of exhaust gas in the cylinder during the intake stroke. This method is more efficient than traditional EGR systems and can provide better emissions control.

Finally, EGR systems are not just used in gasoline and diesel engines. They are also used in some alternative fuel vehicles, such as natural gas and propane-powered vehicles. In these applications, EGR systems help reduce NOx emissions and improve engine efficiency, just as they do in gasoline and diesel engines.

How to Clean an EGR Valve: A Step-by-Step Guide

If you suspect that your EGR valve is clogged with carbon deposits, cleaning it can often restore its proper function. However, cleaning an EGR valve requires some mechanical skill and attention to detail. Before attempting to clean your EGR valve, consult your vehicle's repair manual or a qualified mechanic to ensure that you're following the correct procedure.

First, disconnect the negative battery cable to prevent any electrical shocks. Then, locate the EGR valve on your engine. It's typically located near the intake manifold. Disconnect any electrical connectors and vacuum hoses attached to the valve. Next, remove the bolts or screws that secure the EGR valve to the engine. Once the valve is removed, carefully inspect it for carbon deposits. Use a carburetor cleaner or a specialized EGR valve cleaner to loosen and remove the deposits. You may need to use a small brush or scraper to remove stubborn deposits.

After cleaning the valve, rinse it thoroughly with clean water and allow it to dry completely. Inspect the valve's gasket and replace it if necessary. Finally, reinstall the EGR valve, reconnect the electrical connectors and vacuum hoses, and reconnect the negative battery cable. Start the engine and check for any leaks or abnormal noises. If the engine runs smoothly and the check engine light is off, you've successfully cleaned your EGR valve.

What If EGR Fails?: Consequences and Symptoms

When the EGR system malfunctions, it can lead to a variety of problems, ranging from reduced engine performance to increased emissions and even potential engine damage. The specific symptoms of EGR failure depend on the nature of the problem and the engine design. However, some common symptoms include a rough idle, reduced power, poor fuel economy, a check engine light, and even engine knocking.

One of the most common consequences of EGR failure is increased NOx emissions. When the EGR system is not functioning properly, combustion temperatures can rise, leading to higher levels of NOx in the exhaust. This can contribute to air pollution and potentially damage the catalytic converter. In some cases, EGR failure can also lead to carbon buildup in the intake manifold, which can further restrict airflow and reduce engine performance.

If you suspect that your EGR system has failed, it's important to have your vehicle diagnosed by a qualified mechanic as soon as possible. Ignoring EGR problems can lead to more serious damage and potentially expensive repairs. Early detection and repair can help prevent these issues and ensure that your engine continues to operate efficiently and cleanly.

EGR Listicle: 5 Key Benefits of a Properly Functioning EGR System

Let's break down the advantages of a well-maintained EGR system into a concise list:

- Reduced NOx Emissions: This is the primary benefit, helping to lower harmful pollutants released into the atmosphere.

- Improved Fuel Efficiency: Optimized EGR can lead to better gas mileage by reducing pumping losses.

- Prevention of Engine Knocking: By lowering combustion temperatures, EGR helps prevent premature detonation and engine knocking.

- Extended Engine Life: Reducing engine stress through controlled combustion can contribute to a longer engine lifespan.

- Compliance with Emissions Regulations: A properly functioning EGR system ensures your vehicle meets environmental standards.

These benefits highlight the crucial role EGR plays in maintaining both vehicle performance and environmental responsibility. Regular maintenance and prompt attention to any potential issues will ensure that your EGR system continues to deliver these advantages.

Question and Answer

Q: What does EGR stand for?

A: EGR stands for Exhaust Gas Recirculation.

Q: What is the main purpose of an EGR system?

A: The main purpose is to reduce nitrogen oxide (NOx) emissions by lowering combustion temperatures.

Q: How often should I clean my EGR valve?

A: The frequency depends on driving conditions and vehicle type. Consult your owner's manual, but generally, inspect it every 50,000 to 75,000 miles.

Q: Can I disable my EGR system?

A: Disabling the EGR system is generally not recommended, as it can increase emissions, void warranties, and potentially damage the engine. It may also be illegal in some areas.

Conclusion of Exhaust Gas Recirculation (EGR) – Design, Function & Benefits

The Exhaust Gas Recirculation (EGR) system is an integral part of modern vehicle emission control, playing a vital role in reducing harmful pollutants and improving engine efficiency. While it may seem like a complex system, understanding its design, function, and benefits can empower drivers to make informed decisions about maintenance and care. By keeping your EGR system in good working order, you're not only helping to protect the environment but also ensuring the long-term health and performance of your vehicle. So, next time you see that little valve under the hood, remember the important job it's doing!