Ever wondered why your car isn't quite performing the way the manufacturer promised? Or maybe you're just curious about the inner workings of an engine and how efficiently it's actually using fuel. Two key concepts, often tossed around but rarely fully understood, are volumetric efficiency and mechanical efficiency. Understanding these concepts can unlock a new level of insight into engine performance.

It's frustrating when the numbers on paper don't translate into real-world performance. We often find ourselves chasing performance gains, tweaking different parameters, only to be met with minimal results. Many times, the source of these discrepancies isn't a single component, but rather the interplay of various efficiency factors within the engine itself.

This blog post aims to demystify the differences between volumetric efficiency and mechanical efficiency. We will explore what each term means, how they are measured, and most importantly, how they impact the overall performance of an engine. We'll also dive into factors that influence these efficiencies and explore ways to potentially improve them.

In essence, volumetric efficiency explains how well an engine fills its cylinders with air and fuel, while mechanical efficiency reflects how effectively the engine converts the combustion energy into usable output at the crankshaft. Understanding these concepts, their relationship, and the factors that influence them will equip you with a deeper understanding of engine performance optimization. We'll discuss practical aspects and dispel common myths surrounding these efficiencies.

My First Encounter with Volumetric Efficiency

I remember tinkering with an old carbureted engine years ago, desperately trying to squeeze out more power. I was focused solely on air-fuel ratio and ignition timing, convinced that was the key. I spent countless hours adjusting the carburetor, even swapping out jets, but the results were underwhelming. A seasoned mechanic, witnessing my frustration, chuckled and asked, "Have you considered your volumetric efficiency?"

At the time, the term sounded like technical jargon. He patiently explained that even with the perfect air-fuel mixture, the engine could only produce power proportional to the amount of air it could actually draw into the cylinders. He pointed out factors like intake manifold design, valve timing, and even the engine's operating temperature, all of which played a crucial role. The lightbulb moment was realizing that optimizing the air-fuel mixture was pointless if the engine wasn’t breathing properly in the first place. This changed my whole approach.

Volumetric efficiency is a crucial parameter. An engine with low VE might struggle to produce power. This is true despite the proper fueling and timing. Factors like restricted airflow, poor valve timing, or excessive intake temperatures all contribute to reducing the amount of air that enters the cylinder during the intake stroke. Understanding how to improve VE, through porting the cylinder head, upgrading the intake manifold, or optimizing valve timing, unlocks real performance gains.

Volumetric Efficiency vs. Mechanical Efficiency: The Core Difference

Let's break it down simply. Volumetric efficiency (VE) is a measure of how efficiently an engine fills its cylinders with the air-fuel mixture during the intake stroke, compared to the engine's displacement. Ideally, a 2.0-liter engine would draw in

2.0 liters of air-fuel mixture. However, in reality, this is rarely the case due to restrictions and inefficiencies in the intake system. VE is expressed as a percentage, with 100% representing perfect cylinder filling.

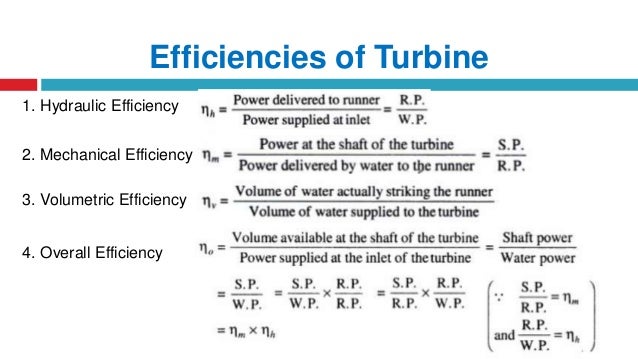

Mechanical efficiency, on the other hand, focuses on how much of the energy produced during combustion is actually delivered as usable power at the crankshaft. An engine loses power due to friction between moving parts (pistons, rings, bearings), the energy required to drive auxiliary components (water pump, oil pump, alternator), and other mechanical losses. Mechanical efficiency is also expressed as a percentage, with higher percentages indicating less energy wasted on internal friction and auxiliary loads.

While both efficiencies are important, they address different aspects of engine performance. VE focuses on the "breathing" of the engine, while mechanical efficiency addresses the losses that occur during the conversion of combustion energy into usable power. Improving both VE and mechanical efficiency results in a more powerful and fuel-efficient engine.

Myths and History of Engine Efficiency

One common myth is that achieving 100% volumetric efficiency is impossible. While true for naturally aspirated engines under most conditions, forced induction systems like turbochargers and superchargers can actually push VE beyond 100%. This is because they force more air into the cylinders than the engine's displacement would normally allow.

Historically, engine development has always focused on improving both VE and mechanical efficiency. Early engines were notoriously inefficient, with low VE due to poor intake designs and low mechanical efficiency due to crude manufacturing processes. Over time, advancements in materials, manufacturing techniques, and engine design principles have led to significant improvements in both areas. The development of technologies such as variable valve timing, direct injection, and low-friction coatings has further enhanced engine efficiency.

The quest for higher efficiency continues today. Manufacturers are constantly exploring new technologies and strategies to reduce losses and extract more power from each drop of fuel. From advanced combustion strategies to lightweight materials, the pursuit of greater efficiency is a driving force in modern engine development.

The Hidden Secret to Maximizing Engine Performance

The real "secret" isn't a single trick, but rather a holistic approach to engine building and tuning. It involves understanding the interplay between volumetric efficiency, mechanical efficiency, and other factors like thermal efficiency (how well the engine converts heat energy into work) and combustion efficiency (how completely the fuel is burned).

Often, focusing on one efficiency at the expense of others can lead to suboptimal results. For example, increasing VE by installing a massive intake manifold might improve top-end power but hurt low-end torque due to reduced air velocity at lower engine speeds. Similarly, reducing friction by using low-viscosity oil might improve mechanical efficiency but compromise engine durability if the oil film is too thin.

The key is to find a balance. A well-designed engine will optimize all aspects of efficiency to achieve the desired performance characteristics. This requires careful consideration of the engine's intended use, operating conditions, and the interaction between various engine components. It's about understanding the complete system, not just individual parts.

Recommendations for Improving Engine Efficiency

If you're looking to improve your engine's efficiency, start with the basics. Ensure that your engine is properly maintained, with clean air and fuel filters, functioning spark plugs, and properly adjusted valve clearances. These simple measures can significantly impact both VE and mechanical efficiency.

For more advanced improvements, consider upgrading components that directly impact VE, such as the intake manifold, exhaust system, and camshafts. Porting and polishing the cylinder head can also improve airflow and increase VE. On the mechanical efficiency side, consider using lightweight pistons and connecting rods, low-friction bearings, and a high-quality synthetic oil.

Finally, don't underestimate the importance of proper tuning. A well-tuned engine will optimize ignition timing and air-fuel ratio for maximum power and efficiency across the entire RPM range. Consider using a dynamometer to measure your engine's performance and make informed tuning adjustments.

Practical Examples of Efficiency Improvements

Let's look at a couple of real-world examples. Imagine you're building a street performance engine. Upgrading to a cold air intake system can improve VE by drawing in cooler, denser air. Pairing this with a less restrictive exhaust system will further enhance airflow, leading to increased power and torque. Furthermore, choosing a high-flow air filter will also help to achieve higher VE.

Now, consider improving mechanical efficiency. Switching to low-tension piston rings can reduce friction and increase power output. Coating the piston skirts with a friction-reducing material can provide an additional boost. When these changes are combined, you can see a noticeable improvement in engine response and fuel economy. It is important to note that such modifications should be done with caution. It is important to ensure that all changes are within the engine's design limits and that you're not sacrificing reliability for performance.

These are just a few examples, but the principle remains the same: identify the bottlenecks in your engine's VE and mechanical efficiency, and then address them systematically. Keep in mind that every engine is different, and what works for one engine might not work for another. Experimentation and careful analysis are key to achieving optimal results.

Tips for Measuring and Analyzing Engine Efficiency

Accurately measuring VE and mechanical efficiency can be challenging, but there are several techniques you can use. For VE, you can use a mass airflow (MAF) sensor or a volumetric flow meter to measure the amount of air entering the engine. Compare this to the engine's displacement to calculate VE.

Mechanical efficiency is more difficult to measure directly. One approach is to measure the engine's indicated horsepower (IHP), which represents the power produced inside the cylinders, and then compare it to the brake horsepower (BHP), which is the power delivered at the crankshaft. The difference between the two represents the power lost due to friction and auxiliary loads. Another method involves performing a coast-down test, where the vehicle is allowed to coast to a stop and the rate of deceleration is measured.

Using Data Logging for Efficiency Analysis

Data logging is invaluable for analyzing engine efficiency. By recording parameters such as MAF sensor readings, RPM, throttle position, and air-fuel ratio, you can gain insights into how the engine is performing under different conditions. You can then use this data to identify areas where VE or mechanical efficiency can be improved. For example, a drop in VE at high RPM might indicate a restriction in the intake system. Reviewing the logged data after changes have been made can confirm if improvements have been made.

Fun Facts About Engine Efficiency

Did you know that the first internal combustion engines had incredibly low thermal efficiencies, often below 10%? That means that more than 90% of the fuel's energy was wasted as heat! Early designs lacked effective cooling systems and efficient combustion chambers, leading to significant energy losses. Modern engines, on the other hand, can achieve thermal efficiencies of over 40% thanks to advancements in design, materials, and combustion technology.

Another interesting fact is that Formula 1 engines often achieve very high volumetric efficiencies, thanks to their sophisticated intake and exhaust systems and meticulously designed combustion chambers. However, they also have relatively short lifespans due to the extreme stresses they endure. It highlights the trade-offs that exist between performance and reliability.

Fun Fact: The highest mechanical efficiency is not always desired! In some racing applications, deliberately introducing friction can improve engine braking, allowing the driver to slow the car more effectively. This is a strategic choice that prioritizes overall performance over pure efficiency.

How to Improve Volumetric Efficiency in Your Engine

Improving volumetric efficiency often involves addressing restrictions in the intake and exhaust systems. Upgrading to a larger throttle body, porting and polishing the cylinder head, and installing a high-flow exhaust system can all significantly increase airflow into and out of the engine. Additionally, optimizing valve timing through the use of performance camshafts can help to maximize cylinder filling.

Another factor to consider is intake air temperature. Denser air contains more oxygen, which can improve VE. Installing a cold air intake system or an intercooler (for turbocharged or supercharged engines) can help to reduce intake air temperature and increase VE. Careful tuning of the engine management system is also crucial. Optimizing ignition timing and air-fuel ratio can ensure that the engine is running at peak efficiency.

Remember that every engine is unique, and the best approach for improving VE will depend on the specific application and existing components. Experimentation and careful analysis are essential for achieving optimal results. Consider using a dynamometer to measure the impact of any changes you make.

What If Volumetric Efficiency Is Low?

Low volumetric efficiency translates directly to reduced power output. If an engine can't fill its cylinders effectively, it won't be able to burn as much fuel, resulting in less torque and horsepower. This can manifest as sluggish acceleration, poor fuel economy, and a lack of responsiveness. A low VE can also indicate underlying problems, such as worn valve guides, leaking intake gaskets, or a clogged air filter.

It's important to diagnose the root cause of the low VE before attempting to fix it. A compression test can help to identify leaky valves or worn piston rings. A vacuum test can reveal intake leaks. A visual inspection can uncover obvious restrictions in the intake or exhaust systems. Addressing these issues will not only improve VE but also enhance engine reliability and longevity.

Ignoring low VE can lead to further problems. A poorly performing engine can put extra strain on other components, such as the catalytic converter, leading to premature failure. Furthermore, inefficient combustion can result in increased emissions, which can contribute to air pollution. Maintaining optimal VE is essential for both performance and environmental responsibility.

Listicle: Top 5 Ways to Boost Engine Efficiency

- Upgrade Your Air Intake: A cold air intake delivers cooler, denser air for improved combustion.

- Optimize Your Exhaust System: A less restrictive exhaust allows for better scavenging and increased power.

- Tune Your Engine: Proper tuning maximizes power and fuel economy across the RPM range.

- Use Synthetic Oil: Synthetic oils reduce friction and improve mechanical efficiency.

- Maintain Your Engine: Regular maintenance ensures that your engine is running at its best.

These five steps are a great starting point. Each upgrade can provide significant improvements to both VE and mechanical efficiency.

Question and Answer about Volumetric Efficiency vs Mechanical Efficiency

Q: What is a good volumetric efficiency number?

A: For naturally aspirated engines, a VE of 80-90% is considered good. Forced induction engines can exceed 100%.

Q: How does altitude affect volumetric efficiency?

A: Higher altitudes mean thinner air, which reduces VE in naturally aspirated engines. Turbocharged engines are less affected.

Q: Can I improve volumetric efficiency without modifying my engine?

A: Yes, ensuring proper maintenance, cleaning air filters, and using high-quality fuel can help improve VE.

Q: What are some common signs of low mechanical efficiency?

A: Reduced power, poor fuel economy, and excessive engine heat can indicate low mechanical efficiency.

Conclusion of Volumetric Efficiency vs Mechanical Efficiency

Understanding the difference between volumetric efficiency and mechanical efficiency is essential for anyone looking to optimize engine performance. Volumetric efficiency explains how well your engine breathes, and mechanical efficiency describes how effectively combustion energy gets to the crankshaft. By focusing on improving both aspects, and understanding the relationship between each, you can unlock the true potential of your engine, enhancing power, fuel economy, and overall driving experience.